Safety takes top priority!

The construction of a new metre-gauge tunnel in parallel to the existing rail tunnel will significantly increase the safety of the railway for the future. This system, with its safety and rescue tunnel, conforms to current technical standards and statutory regulations. If an incident should ever occur, train passengers will be able to use the transverse accesses to enter the “old” Albula Tunnel and safely reached the exit.

Safety tunnel

Once the new Albula Tunnel has been inaugurated, its original counterpart will be decommissioned and converted into a safety tunnel. This involves the following operations:

-

All railway installation facilities, including wiring and cables, are to be removed.

-

Damaged masonry is to be partly restored, and sections of loose rock are to be secured.

-

The tunnel’s drainage systems to be replaced.

-

The tracks are to be removed and a new floor laid.

-

The sprinkler system is to be relocated, and connected to the water supply of the new tunnel.

-

Central ventilation facilities with fans and airlocks are to be installed. These are designed to produce slight excess pressure in the safety tunnel and transverse accesses in the event of a fire, so as to prevent smoke from entering the protected area.

-

Installation of safety systems, lighting and communications equipment.

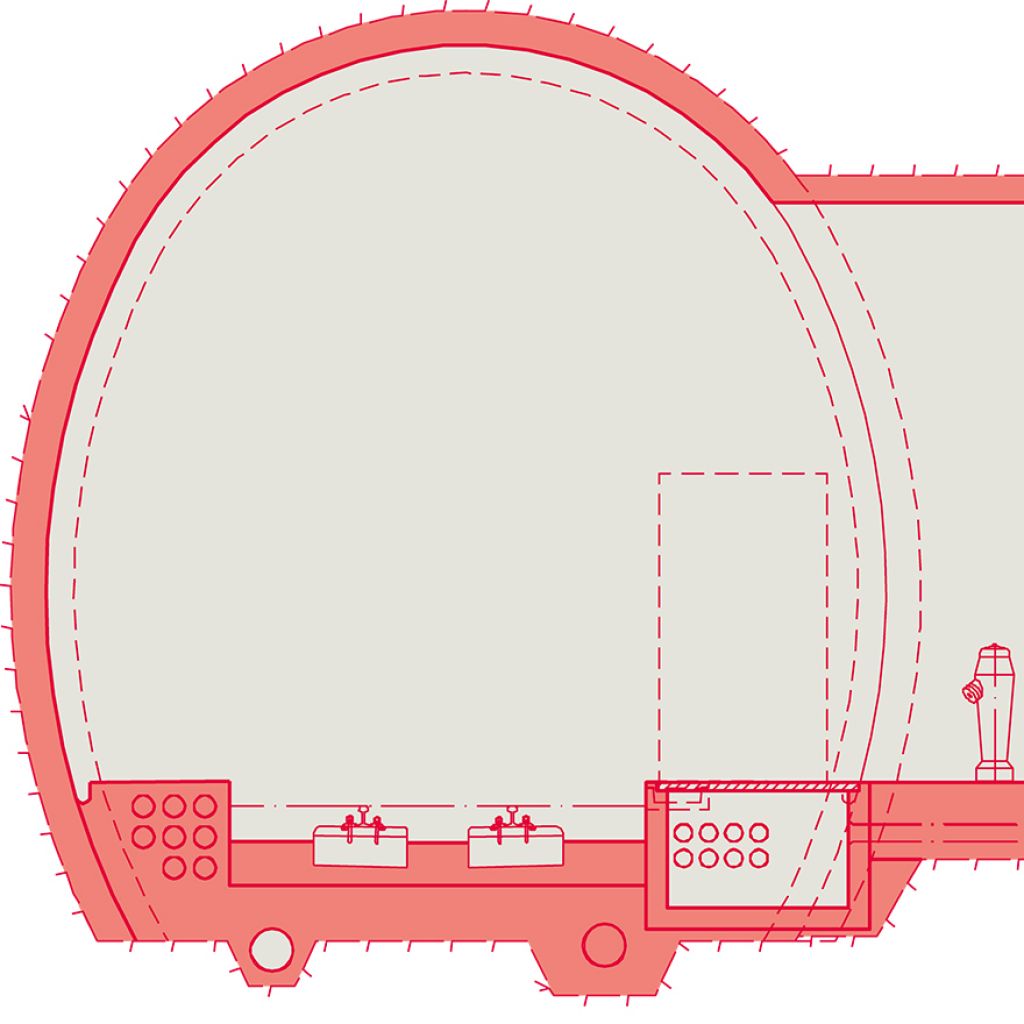

Transverse accesses

The new Albula Tunnel is to be linked to the safety tunnel by a total of 12 transverse accesses. These safety accesses are to be installed at intervals of between 425 and 460 metres. The transverse accesses are characterised by the following features:

-

Rescue vehicles can be driven into three of the transverse accesses, which open out into a trumpet shape for easier entry and manoeuvring.

-

Each of the transverse accesses is 25 metres long.

-

Each transverse access has an easy-to-open, self-securing escape door designed to resist fire for up to three hours.

-

Each transverse access has a system room for electrical and other technical equipment.

Tunnel cladding

The load-bearing internal cladding consists of either site-mixed concrete, or shotcrete. The horseshoe-shaped arch of the tunnel is optimised to match the requirements of the metre-gauge railway. Strips of hard shoulder are laid on both sides of the track to act as walkways for maintenance purposes and in the event of an incident. The hard shoulder also houses the cabling for electrical systems. A one metre-wide evacuation route runs along one side of the track, providing direct access to the safety tunnel. The evacuation route is equipped with a handrail and emergency lighting.

Mountain water and drainage

Once the tunnel excavation has been secured, the arch is to be sealed to allow clean, in-flowing mountain water to be directed into the tunnel’s drainage system. It flows out via the tunnel portals and directly into the surface water. A separate drainage conduit is to be installed along the tunnel floor to handle the waste water resulting from operation of the line. Whenever the tunnel is being cleaned, or if an incident should arise, the soiled water is directed to one of the treatment plants, at the Preda and Spinas ends of the tunnel respectively, for proper disposal.

Railway infrastructure

The permanent way in the new Albula Tunnel consists of fixed, non-ballasted track, rather than the previous configuration of rails laid on ballast. This involves laying the tracks on firmly and precisely positioned slabs of site-mixed concrete. This ensures that any future adjustments of track will be a matter of millimetres only. The high accuracy of the track design reduces wear on wheels and rails, thereby prolonging the useful life of both. Permanent way of this type is also easier to maintain than track laid on ballast.

Motive power

The new Albula Tunnel is to be equipped with an overhead conductor rail, rather than the catenary system used previously. The overhead is to be fitted with circuit breakers at each entrance and in the middle of the tunnel to allow each section to be shut down independently. The line’s system of earth return via the rails has been designed to conform to the very latest technical standards.

Train safety

The system of safety is to be renewed and adapted to the latest operational requirements. A block-post token system installed in the middle of the tunnel will allow the current passing frequency of trains to be virtually halved, to around three minutes. This will help improve the timetabling and punctuality of the Albula Line.

Cable systems

A pair of radiant cables will maintain wireless communications in each of the two tunnels. These are integrated into the RhB’s existing wireless network. A hollow conduit laid in the hard shoulder running along the left-hand side of the new tunnel will house the high-voltage cable, along with other items. All the cables and wiring required for low-voltage power supplies and communications will be installed in pipes and in the surface-mounted cable conduit running along the hard shoulder on the right-hand side. These cables are connected to the corresponding systems in the tunnel, in the equipment rooms and in the transverse accesses to the safety tunnel.